Full-Arch Implant Surgical and Restorative Considerations: Innovative Digital Process Making Use Of a Verification Jig With Pearly Whites

The instant loading of dental implants provides numerous benefits over postponed therapy choices, including (1) the medical stage usually being completed in one browse through, (2) the capability to prepare the pre-established occlusion beforehand to accomplish an instant useful and also aesthetic result, (3) decreasing total treatment time for the clear-cut restoration, and (4) a reduction in the variety of patient sees. As modern technology continues to evolve, so do the variants in methods that have actually been developed to improve the procedure of providing both preoperative and also postoperative treatment. This short article offers technologies that can boost the workflow in manner ins which are necessary to accomplish and also enhance effectiveness success with single and also twin full-arch implant reconstructions. Diagnostics and also Surgical Procedure Phase

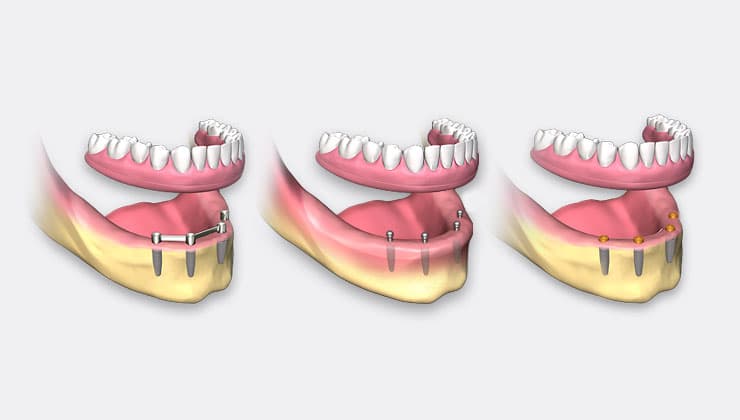

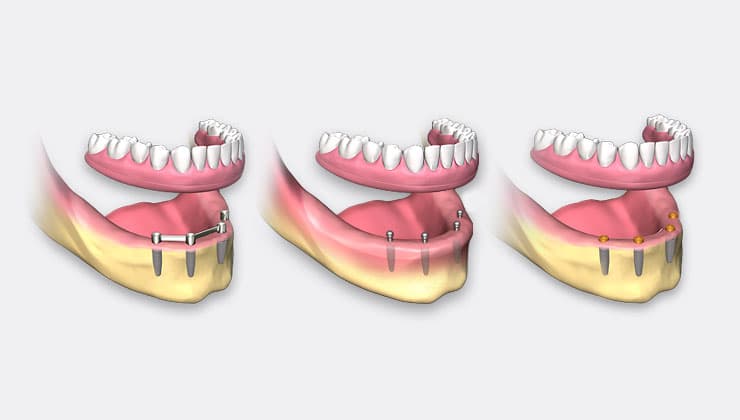

A 58-year-old male offered with a falling short teeth. The pre-op, intraoral, withdrawed sight shows missing out on, damaged, fractured, and decayed teeth and also plaque and calculus accumulation with extreme soft-tissue swelling (Number 1). The client suffered discomfort as well as difficulty eating and also displayed a minimized vertical measurement of occlusion (VDO) as well as hyper-erupted posterior teeth (Number 2). The pre-existing intraoral problem was recorded with perceptions as well as stone casts that were after that digitized with a desktop computer scanner. Additionally, an intraoral check (3Shape) recorded the existing occlusion. The client’s makeup was completely examined with 3-D imaging innovation and interactive treatment preparation software. Cone-beam computed tomography (CBCT) (Carestream Dental) was necessary in being able to imagine the periapical pathology showed by multiple teeth. Making use of the digitized casts, the dental laboratory group finished a digital tooth configuration to establish the right aircraft of occlusion, function, as well as visual appeals. The virtual occlusion was combined to the original teeth to aid in the analysis phase of choosing the appropriate dental implant receptor sites. The dimensions and quantity of the alveolar bone, density and also opacity of the cortical plates, as well as total thickness was essential in reviewing each implant receptor website essential for first security. The positions of the 7 proposed implants were planned to accomplish a screw-retained set repair (Figure 3). It is necessary to note the yellow “estimates,” which expose the trajectory as well as placement of the screw-access holes as they arise with the tooth set-up synopsis (eco-friendly). The red line represents the coronal portion of the implants as well as where the bone will be decreased to produce the necessary corrective space. The surgical stage was intended to use the full-template assisted medical procedure as defined in the very first short article (Dentistry Today, September 2019) as well as, as a result, only summed up here. On the day of surgical treatment, the necessary components included the tooth-borne Addiction Base with Pin Overview, support pins, a bone reduction guide, an osteotomy drill guide, a Service provider Guide, a transitional full-arch prosthesis, and numerous 3-D published designs for both mandibular and maxillary arches (Figure 4) (Chrome GuidedSMILE [ROE Dental Laboratory]. The Addiction Base was first secured to the Pin Overview and then seated on the maxillary teeth. The face anchor holes were drilled via the overview holes in the steel guide, as well as support pins were after that positioned trans-cortically with the buccal surface of the Addiction Base (Figure 5). The teeth were drawn out, and also the bone was leveled as per the medical strategy (red line on cross-sectionals). Based upon the software strategy (BlueSky Strategy), 7 implants were placed (AnyRidge [Mega’Gen]. Making use of vibration frequency evaluation (RFA), implant stability ratios (ISQ [Osstell] were videotaped to figure out enough security for packing. Multi-units were put on each dental implant based upon the tissue elevation and also to reroute the screw-access hole appropriately within the envelope of the repair. Titanium sleeves were after that connected to each dental implant, as well as the Carrier Overview was utilized to properly place the transitional prosthesis to ensure that maybe protected to the implant sleeves with dual-cure composite product (Outstanding DC [TAUB Products] (Number 6). The process was repeated for the mandibular arc. The post-op breathtaking radiograph discloses an exceptional surgical result for both arches after the positioning of 13 implants (Figure 7). The transitional maxillary and also mandibular reconstructions were reviewed for appropriate bite and occlusion (Figure 8). After an adequate recovery time, the prostheses were removed, and the maturation of the soft tissue was evaluated relative to the multi-unit abutments (Figure 9). The panoramic radiograph at 2 months disclosed the transitional screw-retained prosthesis (Number 10).

Restorative Stage

The traditional corrective phase would typically commence with intraoral impressions to connect the dental implant placements to a master actors for the dental laboratory team to design as well as make the clear-cut prosthesis. From the master cast, it would certainly be required to finish a confirmation index of the implants and also figure out the VDO, centric relation, as well as bite enrollment utilizing standard prosthodontic protocols. Nevertheless, existing technology permits the introduction of enhanced electronic process that substantially aid the restorative phase. A combination of analog and digital options were developed gradually with the introduction of the iJIG (ROE Oral Lab). The preliminary purpose of the iJIG was to aid with the style and also construction of a full-arch repair making use of an existing full-arch transitional repair on multi-unit abutments. Simply, the iJIG is a verification jig with teeth. The gadget allows the medical professional to lute easy sections with each other in the mouth, equilibrate the occlusion, record the bite, as well as pick up the intaglio soft cells. This device provides all of the required records to produce a last or model repair. It is also needed to send full-face as well as full-smile images, specifically if aesthetic modifications are desired. The first-generation iJIG included removing the existing transitional prosthesis for digitization with either a 360 ° check from an intraoral scanner or a desktop computer scanner. The prosthesis was after that reseated to scan the opposing arch as well as to digitally tape the bite connection. The initial generation sufficed in idea but extremely challenging for both the medical professional as well as the oral laboratory service technician attempting to decipher the images of the cyndrical tubes and also trajectory of the gain access to openings to straighten the parts. To overcome this problem, special iJIG analogs (ROE Dental Lab) were created to properly capture the placement of the implants and also prosthetic parts. The third generation made use of CAD software application to establish electronic tooth arrangements with physiological teeth that were used to make up for the worn and also equilibrated teeth as a result of feature during the recovery stage. The Generation 4 iJIG is a prosthetic device that was designed based on the principle of “see your smile prior to surgery.” With CHROME GuidedSMILE (ROE Dental Lab), most clients receive a virtually true-to-form smile simulation and also succeeding online tooth arrangement based on conventional triangulation language (STL) electronic documents that imitate the simulation. Throughout the planning phase, the implants were located based upon the combining of intraoral scans or digitized stone situations in mix with the transitional prosthetic layout exported as an STL file. Therefore, the original dental implant and also tooth-planning phase rendered a suitable set up STL file based upon the substitute smile design and saved in the computer until the last restorative phase began. The new STL data of surgical/prosthetic/intraoral scans were combined with the initial tooth arrangement. The new iJIG was after that produced based upon the previously approved and also real shift prostheses put on during the recovery phase. This replica was after that used to register mild modifications in implant position, soft tissue, occlusion, as well as aesthetics. The top and lower iJIGs were sectioned as well as held together with a clear, vacuum-formed overlay for seating and after that intraoral luting (Number 11). Each section was tightened up onto the multi-unit joints as well as approximated to be luted together with either flowable composite or autopolymerizing or dual-cure material (Figure 12). It was very important that all sections were completely seated and passive. It is suggested that the fit of the prosthesis be validated with radiographs. After mindful luting, the full-arch try-in prosthetic was eliminated, and also tray adhesive was applied to the intaglio surface area and circumferential margins. The prosthesis was returned, and a plastic polysiloxane impact material (Aquasil [Dentsply Sirona Restorative] was then injected using syringe to record the tissue user interface and bite relationship (Number 13). The prostheses with perception product connected and the bite registration were then sent out to the laboratory for handling. A stone version was then created from this perception to record the area of the multi-unit joints (Number 14). When the oral lab group received the new information, it was digitized and also participated in the CAD/CAM software program to complete the style (exocad DentalCAD software application [exocad]. It is essential that the placement of the implants be properly stood for with the suitable analogs within the software program collection. The digitally verbalized maxillary as well as mandibular arches can after that be preferably created based upon the updated info to correct any occlusal modifications, cells gaps, aesthetic factors to consider, and/or functional modifications (Figure 15). Based upon the brand-new digital layout, resin-based, 3-D printed, scientific prototypes were made and examined intraorally (Figure 16). Just recently, the fifth-generation iJIG introduced a more anatomical development layout with the addition of an intraoral soft-tissue check. As previously described, the pre-op problem was caught with an IOS (Figure 17). After the recovery phase was completed, an IOS was made use of to tape the position of the MUAs and also the bordering soft tissue for both the maxillary as well as mandibular arches (Number 18). Making use of the iJIG unique scanning analogs connected to the implants, the whole prosthesis was then checked and also digitized extraorally and merged with the opposing arc and bite scans as previously described (Number 19). The intro of the soft tissue help in the style of the model iJIG in developing the material-to-ridge relationship of the final prosthetic tooth setting, tissue contours, cantilevers, etc. The iJIG and also resin-try-in stage offer the clinician with essential information to deliver a more accurate and predictable last repair. The sixth generation requires the formerly explained seating treatments. The details was once more presented right into the CAD/CAM software program (3Shape) to finish the style of the last prosthesis, considering all adjustments in occlusion and also appearance (Number 20). The lateral views of the virtual style are illustrated in Number 21. The final, screw-retained monolithic zirconia remediations were supplied for both arcs. The screw-access openings were first covered with polytetrafluoroethylene (PTFE) tape, adhered to by a composite filling (Figure 22). The final prosthesis can be visualized in the retracted views, revealing an acceptable functional as well as aesthetic outcome (Figure 23). The last prosthesis could be fabricated in nano-bonded-to-titanium, zirconia or nano-bonded-to-trinia, which are both Crystal Ultra (Digital Dental) materials.IN SUMMARY

With mindful medical diagnosis and treatment planning, it is possible to predictably handle full-arch, immediate, implant-supported reconstructions. The initial of our 2-part series explained the 3-D evaluation of person anatomy to give the plan for tooth extraction, bone reduction, and also instant implant placement with concomitant transitional repair made possible with a cutting-edge full-template, assisted remedy. The article even more described a stackable overview system that supplied a combination of a drill overview, a bone decrease guide, an implant insertion guide, and also a web link to the full-arch maxillary remediation. This 2nd installment of the 2-part series defined the actions needed to complete a synchronised dual-full-arch prosthetic restoration after the confirmation of osseointegration and satisfactory soft-tissue growth bordering the multi-unit, screw-receiving abutments. Conventional analog prosthetic protocols have required intraoral impacts that capture the implant abutments within a stone master cast to be installed on an articulator at the appropriate upright and also centric relation position. The oral lab service technician was then charged to produce a wax-up with denture teeth to verify the bite, lip support, pronunciations, and also appearances. From this analog protocol, a screw-retained, clear-cut repair was completed. It was not up until the electronic workflow and also progressed CAD/CAM software program that enabled digitization of the analog configuration to create an online style and also resultant STL files for manufacture of full-arch monolithic zirconia reconstructions. To enhance the digital process, the development of the time-saving gadget, the iJIG, existed. As previously defined, the instant loading of oral implants for full-arch reconstruction uses many advantages over postponed therapy choices, however it does need a premade prosthesis at the time of surgical treatment. For the purposes of this post series, the transitional reconstructions were all digitally developed as well as produced with an almost true-to-form smile simulation for shipment by means of a stackable overview system at the time of surgery. The existing iteration of the iJIG manages the small distinctions from the original transitional reconstruction to the wanted last remediation with a time-saving as well as precise innovation. The iJIG works with many implant systems, such as incorporated dental systems, Nobel Biocare, BioHorizons, NeoDent, Straumann, Hiossen, Thommen, and Keystone. Various other systems, which include Zimmer Biomet, Implant Direct, CAMLOG, Dentsply Sirona Implants, MIS Implants Technologies, Paltop, and others, require details OEM (initial equipment manufacturer) MUA replicas to accurately scan the prosthesis. The iJIG can possibly lower corrective time to 3 sees. Today study required bone reduction to attain the required corrective space for the completion of effective dual-full-arch FP-3 prostheses utilizing the Chrome GuidedSMILE principle with advanced digital operations. The very same full-template led protocols have likewise been shown in cases where conservation of the alveolar and interproximal bony architecture was wanted, which resulted in an FP-1 prosthetic (pink-free) design, or when zygomatic implants were to be utilized to sustain a repaired remediation demanded in a significantly skeletal maxillary arc. Much more research as well as added multi-center researches will assist in comprehending the lasting success of these cutting-edge medical and corrective protocols.